Welders are one of the most important appliances when you are working on DIY home projects, professional fabrication, or even outdoor constructions. Welders require varying power levels that depend on their type and amperage, and using an underpowered generator can lead to inefficient performance or equipment damage. When choosing different backup options, most wonder what size generator to run a welder?

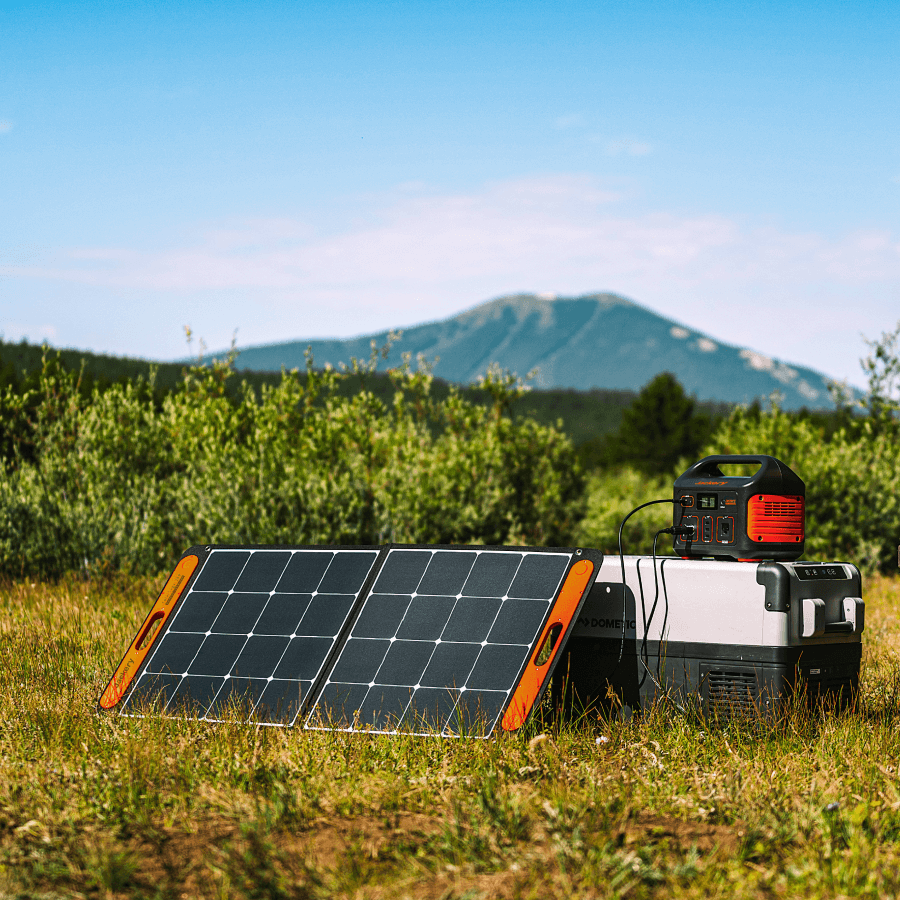

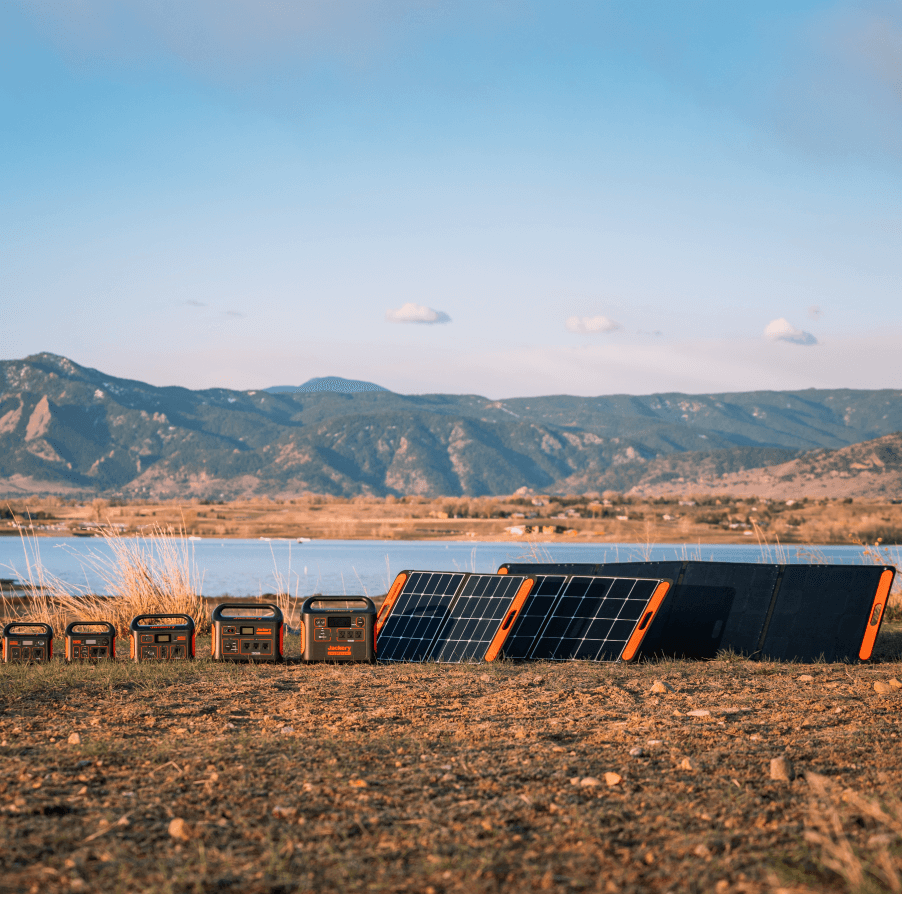

For those seeking a cost-effective, eco-friendly solution, solar-powered generators and portable power stations from Jackery can provide an excellent off-grid power source for low to medium welding tasks. Such portable and compact solar generators are beneficial for outdoor welding jobs where access to on-grid power is limited.

Key Takeaways

- The right generator to run a welder must match the welder’s voltage, amperage, and duty cycle, with additional capacity to handle starting wattage surges.

- Diesel and gasoline generators remain the primary choices for welding, but they have fuel costs, maintenance needs, and noise concerns.

- Solar-powered generators like Jackery Solar Generator 5000 Plus provide a fuel-free alternative for welding applications.

- Always choose a generator with at least 25–30% extra wattage beyond the welder’s running power.

How Many Watts Does a Welder Use?

Before answering what size generator to run a welder, it’s important to understand wattage needs. Just like most heavy-wattage appliances, the power requirement of a welder depends on several factors, like its type, amperage, and duty cycle. In short, a generator must provide more wattage than the welder’s peak power demand to prevent overload.

Understanding Welder Wattage Needs

Most welders operate between 3,000W and 10,000W, but the exact requirement varies based on:

- Welder Type: MIG, TIG, Stick, and Plasma Arc welders have different power demands.

- Voltage & Amperage: Higher amperage and voltage require larger generators.

- Duty Cycle: A higher duty cycle (more continuous welding) requires a generator that can sustain power for extended periods.

How Many Starting & Running Watts Do Welders Use?

When a welding machine is turned on, it requires a short surge of power to establish the welding arc that would lead to ionizing the welding material and generating the required heat. This sudden spike that lasts for only a few seconds is higher than the running wattage.

For example, a TIG welder that operates at 4,500W running power might surge up to 7,000W upon startup. Here are the most common welders, along with respective starting and running wattage:

|

Welder Type |

Starting Wattage (W) |

Running Wattage (W) |

|

MIG Welder (120V) |

5,000W |

3,000W |

|

TIG Welder (240V) |

7,000W |

4,500W |

|

Flux-Cored Welder |

4,500W |

2,800W |

|

Spot Welder |

8,000W |

5,500W |

|

Plasma Arc Welder |

9,000W |

6,500W |

|

Laser Welder |

10,000W+ |

8,000W+ |

|

Electron Beam Welder |

12,000W+ |

10,000W+ |

|

Oxy-Fuel Welder |

Minimal (Non-electric) |

N/A |

|

Ultrasonic Welder |

3,000W |

2,000W |

It should be noted here that:

- If a generator does not meet the starting wattage demand, it will not be able to turn on the welding machine.

- If a generator’s running wattage is too low, then the welder will automatically shut down.

How Much Energy is Needed to Run a Welder?

The energy required to run a welder for home or outdoor operations depends on several key factors, including welder type, input voltage, amperage draw, efficiency, and duty cycle. Unlike common household appliances like portable fans, televisions, laptops, or even a standard electric heater that have a fixed wattage consumption, welders have variable power demands due to the nature of arc welding.

To accurately determine the energy needed, we must break it down using electrical formulas, real-world welding scenarios, and machine specifications.

Energy Formula for Welders

In order to calculate the power required, we use the general formula:

Power (W) = Voltage (V) x Amperage (A)

However, since welders do not run continuously as they operate in cycles, the total energy consumption (kWh) over time can be calculated as:

Energy (kWh) = [Voltage (V) x Ampere (A) x Duty Cycle(%)]/1000

In the above formula:

- Most welders run on 120V, 240V, or even of 480V

- The higher the amperage, the more energy is required by this appliance.

- The welder is not running 100% of the time, so we need to consider its duty cycle, which is the percentage of a 10-minute period during which a welder can safely operate.

Energy Consumption Scenarios for Different Welding Jobs

In order to fully understand the power requirements of different welders, here are a few real-world scenarios and examples that would give you a proper idea and help you understand what size generator to run a welder is needed for home and outdoor activities:

Small-Scale Welding: For this example, let’s take a MIG welder (140A) running at 120V, 25A, and a 40% duty cycle. Here:

- Power Consumption (W) = 120V x 25A = 3,000W

- Energy Required Per Hour (kWh) = (3000W x 40%)/1000 = 1.2kWh

Medium-Scale Welding: Let’s consider that you have a MIG welder (180A) running at 240V, 30A, and a 50% duty cycle. Here:

- Power Consumption (W) = 240V x 30A = 7,200W

- Energy Required Per Hour (kWh) = (7,200W x 50%)/1000 = 3.6kWh

Industrial Welding: Suppose for heavy-duty fabrication, you have a TIG welder (200A), running at 240V, 50A, and 60% duty cycle. Here:

- Power Consumption (W) = 240V x 50A = 12,000W

- Energy Required Per Hour (kWh) = (12,000W x 60%)/1000 = 7.2kWh

Types of Generators Suitable to Run a Welder

When selecting a generator to run a welder, it is crucial to consider power output, fuel type, portability, and efficiency. When wondering what size generator is needed, you will also first need to understand that the ideal choice depends on the welder's amperage, the duty cycle, and whether you are going to conduct the operation indoors, under the shed, or in off-grid remote locations.

Here are the most common generators that are suitable to run a welder:

Conventional Gasoline Generators

Gasoline generators are among the most commonly used for welding applications, especially for DIY hobbyists, mobile welders, and small workshops. These generators offer high power output, which makes them ideal for running welders that range from 90A to 200A.

Diesel-Powered Generators

If you intend to use heavy-duty industrial welding, then a diesel generator can be an ideal choice due to its high efficiency and durability. These generators provide a stable power supply with higher fuel efficiency than gasoline generators, which makes them suitable for professional fabrication shops, construction sites, and high-amperage welders (200A+).

Inverter Generators

Inverter generators are considered ideal for precision welding, like TIG welding or auto-body repair work, where you will require a stable and clean power supply. Unlike conventional generators that produce fluctuating AC power, inverter generators convert AC power to DC and back to AC, which further ensures a consistent sine wave output with minimal voltage fluctuations.

Solar-Powered Generators

If you want an eco-friendly, noise-free, and portable backup solution for running a welder, you should check out solar generators. Most solar-powered generators have a high battery output, making them a good alternative to diesel-based generators.

What Size of Generator to Run a Welder?

Choosing the right size generator to run a welder is crucial for ensuring smooth and uninterrupted operation. The final generator that you will use must provide sufficient running wattage that would sustain the welder’s energy demands but, at the same time, will also handle the starting surge wattage that occurs when the arc ignites.

For most welding applications, a generator between 3,000W and 8,000W is recommended, but the exact size depends on the welder’s voltage, amperage, and duty cycle. In order to determine what size generator to run a welder, check out the following step-by-step guide:

Step 1: Determine the Power Requirements of the Welder

The first step to answering what size generator to run a welder is to identify its voltage and amperage draw. This information is usually present in the user manual, or you can even calculate using the formula mentioned here:

Suppose we are using a MIG Welder (140A) with a 120V input and a 25A draw, then:

Power (W) = Voltage (V) x Amperage (A) = 120V x 25A = 3,000W

This formula gave us the running wattage of the welder. However, we should also consider the surge wattage, which is usually 30-40% higher than the running wattage. In that case:

Surge Power = 3,000W + (3,000W x 50%) = 4,500W

Step 2: Account for Additional Power Surges

Most welders experience power spikes when igniting the arc, which further increases the starting wattage requirement. When learning about what size generator to run a welder, it is important to choose a generator that provides this extra capacity that prevents overloading.

As mentioned above, the MIG Welder (140A) requires 4,500W during startup, but for safety reasons and to account for safety and efficiency, let’s add a 25% margin to the running power.

Running Power = 3,000W + (3,000W x 25%) = 3,750W

Step 3: Consider Duty Cycle & Runtime Needs

The duty cycle is crucial when determining the size of the generator needed for a welder. This duty cycle represents the percentage of time it can operate within 10 minutes before it needs to cool down. A higher duty cycle would mean the welder runs longer, which would then require a generator that can sustain extra power output over extended periods.

If the MIG Welder (140A) has a 40% duty cycle, it can operate for 4 minutes out of every 10.

Recommended Generator Size = Running Wattage x (100/Duty Cycle)

= 3,750W x (100/40) = 9,375W

This means that since the welder will run continuously at a 40% duty cycle, you should go ahead with a 9,500W generator to ensure stable power output.

Step 4: Factor Additional Load

If you plan to use other appliances alongside your welder, you should also account for their loads. For instance, if you plan to use an angle grinder (1,500W) and a cooling fan (500W) with your MIG welder (140A) that consumes 3,750 running wattage, then:

Power Requirement = 3,750W + 1,500W + 500W = 5,750W

Power Requirement (accounting for surge wattage) = 5,750W + (5,750W x 50%) = 8,625W

To accommodate additional tools, you can go ahead with a generator with at least 9,000Wh or 9.0kWh capacity.

How to Calculate Cost Per Hour Usage of a Welder

The cost of running a welder per hour depends on factors such as welder wattage, usage duration, electricity grid rates, and fuel consumption for diesel generators. When running welders on grid electricity, the cost is calculated based on kilowatt-hour (kWh) usage multiplied by the grid electricity rate. However, when using a diesel generator, the cost is influenced by fuel consumption (gallons per hour) and current fuel prices.

In order to understand the cost of running a welder per hour, let's consider a few factors:

- A 10kW diesel generator at 50% load consumes 0.53 gallons per hour.

- According to the EIA, the cost of diesel in February 2025 is $3.68 per gallon.

- EIA further reveals that the average electricity rate in the United States is ¢16.26kWh.

Below is a detailed breakdown of the cost per hour of running different welders, comparing grid electricity rates and diesel generator costs.

|

Types of Welders |

Usage Duration |

Welder Wattage |

Energy Used (kWh) |

Grid Cost |

Diesel Generator Cost |

Solar Generator Cost |

|

MIG Welder (140A) |

1 hour |

3,000W |

3.0kWh |

$0.48 |

$1.17 |

$0.00 |

|

MIG Welder (140A) |

5 hours |

3,000W |

15.0kWh |

$2.43 |

$5.85 |

$0.00 |

|

TIG Welder (200A) |

1 hour |

7,200W |

7.2kWh |

$1.17 |

$2.80 |

$0.00 |

|

TIG Welder (200A) |

5 hours |

7,200W |

36.0kWh |

$5.85 |

$14.0 |

$0.00 |

|

Stick Welder (225A) |

1 hour |

10,000W |

10.0kWh |

$1.62 |

$3.90 |

$0.00 |

|

Stick Welder (225A) |

5 hours |

10,000W |

50.0kWh |

$8.13 |

$19.50 |

$0.00 |

As you can see from the above cost analysis, the hourly diesel generator cost to run a MIG Welder (140A) is $1.17, which seems low. However, if the welder runs 8 hours per day for 30 days, the monthly fuel cost alone would be $280.80. Over the course of a year, this translates to $3,369.60 just in fuel expenses.

Here, we have not accounted for the upfront cost of purchasing a high-quality generator ($4,000 - $11,000), nor does it include transportation and maintenance costs. These ongoing expenses make diesel-powered generators a costly long-term solution for welding applications. If you want a reliable, affordable, and eco-friendly solution, you can check out solar-powered generators, which offer alternatives that eliminate fuel costs entirely and involve only one-time investment.

Best Jackery Solar Generators to Run Welder

Jackery is a leading manufacturer of solar generators, solar panels, and portable power stations, known for delivering reliable, clean energy solutions for both home and outdoor applications. With over 5 million units sold worldwide, Jackery has revolutionized how people access off-grid power, offering a sustainable alternative to traditional fuel-powered generators.

Jackery Solar Generators’ high-capacity battery can support different welding applications, making them an ideal backup solution for different welding tasks, off-grid projects, and power outages. Some of the highly recommended solar generators for welders are:

Jackery Solar Generator 5000 Plus

For welders who need a powerful and reliable off-grid energy solution, the Jackery Solar Generator 5000 Plus offers an impressive balance of high-capacity power and portability. Whether you are tackling metal fabrication in remote locations or need a backup power source for different welding tasks, this solar generator ensures consistent energy output to 120V or 240V welders without the hassle of fuel costs or noise pollution.

Appliance Working Hours

- Stick Welders (1500W) = 2.7H

- MIG Welders (2000W) = 2.0H

- TIG Welders (1500W) = 2.7H

- Plasma Arc Welders (3000W) = 1.4H

- Ultrasonic Welder (2000W) = 2.0H

Customer Review

“The Jackery Explorer 5000 Plus is a superior choice for anyone in need of dependable and versatile power solutions.” -- Christian.

Jackery Solar Generator 2000 Plus

For DIY welders, hobbyists, and on-the-go repair professionals, the Jackery Solar Generator 2000 Plus provides a lightweight yet capable power source for low to mid-range welding tasks. What makes the Jackery Solar Generator 2000 Plus different from the others is its expandable capability, which makes it an ideal companion for portable, light-duty welding applications operating at 120V, allowing one to work off-grid without relying on diesel or gasoline-powered generators.

Appliance Working Hours

- Stick Welders (1500W) = 1.1H

- MIG Welders (2000W) = 51 min

- TIG Welders (1500W) = 1.1H

- Plasma Arc Welders (3000W) = 34 min

- Ultrasonic Welder (2000W) = 51 min

Customer Review

“Our new Jackery Explorer 2000, extra batteries, and Solar Saga 200 panels work as expected and perform well. The system is able to power a heat lamp for our chickens overnight reliably.” -- Savvy Organics Farm.

What Size Generator to Run a Welder FAQs

How do I calculate what size generator I need for my welder?

To calculate the right generator size for your welder, you need to determine the running wattage, starting wattage, and duty cycle of your welding machine. For example, a 120V MIG welder drawing 25A has a running wattage of 3,000W, but with a 50% surge factor, the required generator size increases to 4,500W or more.

Can a 3000-watt generator run a welder?

Yes, a 3,000W solar generator is suitable for small welders, particularly MIG or flux-cored welders operating at low amperage settings, but it is not powerful enough for mid- to heavy-duty welding applications.

What size generator to run a 140-amp welder?

A 140-amp welder typically runs on 120V and draws about 25–30A, which means that its running wattage requirement is around 3,000–3,600W. However, welders experience a startup power surge, so you should add at least 50% extra capacity, which would bring the total requirement to 4,500–5,500W.

How many watts of a generator can run a 200-amp welding machine?

A 200A welder running at 240V draws around 50A, which means its running wattage requirement is approximately 12,000W. However, welders have a surge wattage that can be up to 50% higher, so to accommodate startup power spikes, you should have a generator that provides at least 15,000W to 18,000W.

What size generator do I need to run my MIG welder?

A small MIG welder (90A–140A) running at 120V usually requires a 4,500–5,500W generator, while a mid-range MIG welder (180A) running at 240V will need 8,000–10,000W for stable performance. If you are using a high-powered MIG welder (200A+), it is best to opt for a 12,000–15,000-watt generator to handle the high energy demand and prevent power fluctuations.

Conclusion

What size generator to run a welder is a critical question for anyone relying on welding equipment in workshops, construction sites, or remote locations. The right generator must meet the welder’s voltage, amperage, and duty cycle requirements while also accounting for starting wattage surges. Traditional gasoline and diesel generators offer stable power for industrial welding, but Jackery Solar Generators provide an eco-friendly alternative for off-grid welding needs. By carefully assessing your welder’s power consumption and choosing a generator with at least 25–30% extra capacity, you can ensure consistent power delivery, stable arc performance, and long-term efficiency.

Leave a comment