A 7kVA-13kVA (Kilo-Volt-Ampere) generator can run a 120V-240V welder. Calculating the size of a generator for a welder depends on how much power or wattage (W) it consumes. If you consider a 120V welder drawing 10A or ampere, its wattage consumption would be the voltage multiplied by the ampere. Hence, the wattage of a 120V welder would be 1200W, and that of a 240V welder drawing 10A would be 2400W.

You need a generator size that can fulfill this power consumption without overloading. Finding the ideal size also depends on your generator and your welder's use cases, including emergencies like hurricanes, power outages, or outdoor projects. A solar generator is one of the best types of generators to charge a welder. You can use Jackery Solar Generators to run a welder safely, without noise emission, and for long hours, if needed.

Key Takeaways

To understand how to use a generator for welders, this comprehensive guide will help you cover the following guidelines:

- Generator power uses gas, diesel, inverter or solar energy whereas main power outlets use electricity.

- Use a generator for weldingto ensure a consistent power supply without any interruptions.

- Look at the size of the machine and the thickness of the metals being welded to determine the amount of electricity used by a welder.

- You can choose between gas, diesel, inverter, or solar generators to operate your welding equipment.

Generator Power vs. Main Power

While using welding equipment for different fabrication needs, including cutting and fusing metal or thermoplastics, you may consider the power supply it requires. Generator power can rely on diesel, gas, inverters, or solar generators to supply current to your welding machine. The main power is your primary power outlet, which supplies electricity to different equipment and tools used for welding.

Generator Power

This is a backed-up source of power that you can use when you don’t have access to the main power outlet. It has a limited capacity, depending on the type of generator you use. The size of your generator would determine how many appliances it can charge fully.

Pros:

- Using generators for weldingcan guarantee a continuous electricity supply for long hours.

- They can serve as emergency power supplies during power outages.

- If you use a solar generator, you can execute your welding tasks throughout the day using the sun’s radiation to charge your equipment. If there is enough stored power left, you can use it throughout the night, depending on the power usage of your welder.

- They are portable and can be used for indoor and outdoor welding scenarios, including remote locations.

- They can be used to charge inverter welding machines that are impossible to run by accessing the main’s power.

Cons:

- Welders are sensitive equipment containing inverters that can be damaged by a voltage spike caused by generator power.

Main Power

This is your primary power source, and you can use it to charge different welding equipment and other electrical appliances. However, you cannot utilize it during power outages.

Pros:

- A main outlet ensures a consistent flow of power, preventing damage to your welding equipment.

- It can be used for various industrial equipment, ranging from small to high voltages, without fear of damage to the equipment.

Cons:

- The voltage of running a welder using the main power is too high and can damage the inverter inside the equipment.

- You might not always get a main or direct power outlet in remote locations to run your welding machine.

- The cost of relying on main power for long hours can burn a hole in your pocket.

- You can’t use the main power source during a power outage.

- It is not a portable source of power.

Why Do You Need A Generator for A Welder?

You can use a generator for a welder to ensure a consistent power supply without any interruptions. For instance, say you are welding the rusted corners of your garden fence, and there is a power outage. In this scenario, generators for welding ensure backed-up power that can help you continue your work. You can also use generators in the following scenarios:

During Emergencies

You might encounter an emergency, especially during hurricanes or storms, when you cannot access a power outlet for hours or days. In this case, using a generator for a welder is a convenient way of continuing projects without any delays.

During Temporary Power Outages

According to Statista, 80% of power outages in the U.S. are caused by weather conditions like hurricanes, hail, and storms. These outages last for nearly three to five hours. Using generators for welding can save time and limit electricity consumption, as your backup power source runs on diesel, gas, or solar energy.

During Outdoor Welding

You might be working on a construction project outdoors or at a remote location. The main power source might be limited or nonexistent. Generators reliant on solar energy, diesel, or gas can provide the required electricity for running your welding equipment.

How Much Electricity Does A Welder Use?

A welder of 120V-240V or voltage consumes between 1200-2400W or wattage of electricity if run on 10A or amperage. This primarily depends on the size of the machine and the thickness of the metals being welded. To understand this, let’s take a look at the basics.

Volts

Volts are a short form of voltage and electric pressure. The electric pressure pushing the current with a wire is called a volt. Electricity from the electric grid is measured in 120V and 240V. General home appliances like lights, televisions, fans, chargers, and computers use 120V power. Heavy electric items like air conditioners, clothes dryers, heating systems, etc., use 240V power.

To calculate, Volt = Watts / Amps

Amps

Amp is a short form for amperage. Amp is one way of measuring electricity that runs through any circuit. The measurement is generally 15 amps, 20 amps, and 30 amps. The electrical socket and general lighting will rate at 15 amps. The 20 amps are commonly found in the new laundry room, kitchen, refrigerator, and bathroom constructions. Large devices like electric cloth dryers run at 30 amps.

To calculate, Amps = Watts / Volts

Watts

Watt is the short form of wattage, which is the amount of power consumed by any electrical device. One watt is calculated by multiplying the amps and volts. In short, wattage is the power generated when the device is operated. For microwaves, televisions, and similar items, the power is calculated in watts.

To calculate, Watt = Amps x Volts

kVA

kVA is a short form for Kilo-Volt-Amperes. It measures the apparent power of the power source and is defined by the total amount of power used by the device or machine.

To calculate, kVA = Volts x Amps

Welders consume 120V and 240V of electricity. There are three types of welding machines, which are heavy appliances that consume less or more power. Based on many other factors and welding activity, the power consumption is both 120V and 240V.

In addition to this, you may consider the below-mentioned factors that might affect the power consumption of your welding machine:

Efficiency

If your welding machine has efficient transformers and circuit correctors, it can maintain a consistent power supply without spikes.

Environment

You should avoid welding in high humidity. Environments with high temperatures provide more pressure on appliances to run smoothly. This results in the appliance drawing more power than usual.

Metal Thickness

Thicker metals like steel require more power consumption because the heat produced to weld them is greater. This is one of the key factors in increasing welding power consumption.

Welding Technique

Your welder's power consumption will vary depending on the welding technique you use. For instance, if you opt for MIG welding, you will need more power since this type of welding operates on high-circuit arcs.

Wire Feed Speed

This is a considerable factor if you’re doing MIG welding. Since more power is needed to maintain the arc and produce heat, the welder draws more electricity to run smoothly.

Duty Cycle

Your welding machine has a duty cycle or percentage that can operate smoothly before cooling down. Welding techniques like MIG welding, which require higher-circuit arcs, have higher duty cycles since they continue for longer periods. Hence, they draw more electricity.

Types of Generators for A Welder

Finding the correct generator for a welder is crucial to efficiently completing your welding project. You can choose between gas, diesel, inverter, or solar generators to operate your welding equipment.

Gas Generators

Gas generators use gasoline or natural gas to convert the gas into mechanical energy to run different welding appliances. This is done via combustion. Since they require a gas line, the maintenance cost can increase over time.

Diesel Generators

Considered a more expensive alternative, diesel generators are great for construction projects in snowy climates. The fuel is a warm source of energy that is converted into mechanical energy to run the generator. They can also power heavy-duty welding appliances.

Inverter Generators

These generators are known for their quiet operation and run entirely on green and clean energy. Inverter generators convert DC (direct current) into AC (alternating current), which is a cleaner and easier process than standard generators. They are fuel-efficient and safe to use for sensitive equipment like welders. You can buy a small inverter generator as a backup power source for your welding needs.

Solar Generators

These generators convert the sun’s radiation into electricity and are considered eco-friendly. They are safe for indoor and outdoor projects and are usually emission-free. They are portable and cost-effective in the long run. Jackery Solar Generators are some popular options, providing reliability of usage, efficiency, and safety of welding appliances.

You can look at the table below to understand the pros and cons of all the different kinds of generators for a welder.

|

Generator |

Pros |

Cons |

|

Gas Generator |

● You can access gasoline or natural gas through a pipeline. |

● The cost of maintaining the pipeline can be expensive over time. ● Gas generators have higher emissions than diesel, inverter, and solar generators. |

|

Diesel Generator |

● These generators are ideal for handling heavy-duty equipment. ● They have low emissions in comparison to gas generators. |

● The cost of running a generator using diesel fuel is on the pricier end of things. |

|

Inverter Generator |

● Inverter generators operate on clean and efficient fuel. ● They are smoke and noise-free. ● They are lightweight and portable. |

● They can only be used to run small welding appliances. ● They are known as sensitive equipment and can be easily damaged by spikes in the voltage from a power outlet. |

|

Solar Generator |

● They are portable and convenient alternatives to a regular power source. ● They are smoke and noise-free. ● They have no fuel costs and can be operated even in remote locations. |

● They are reliant on the sun’s radiation. ● They have a lower power output than diesel generators. |

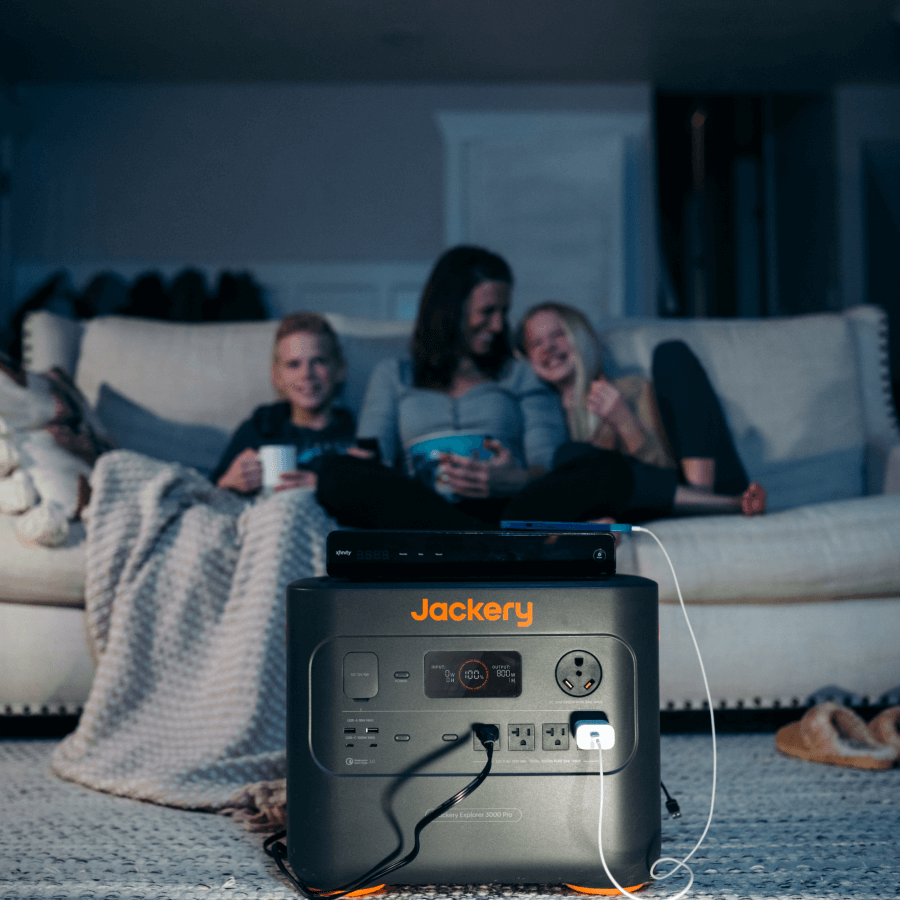

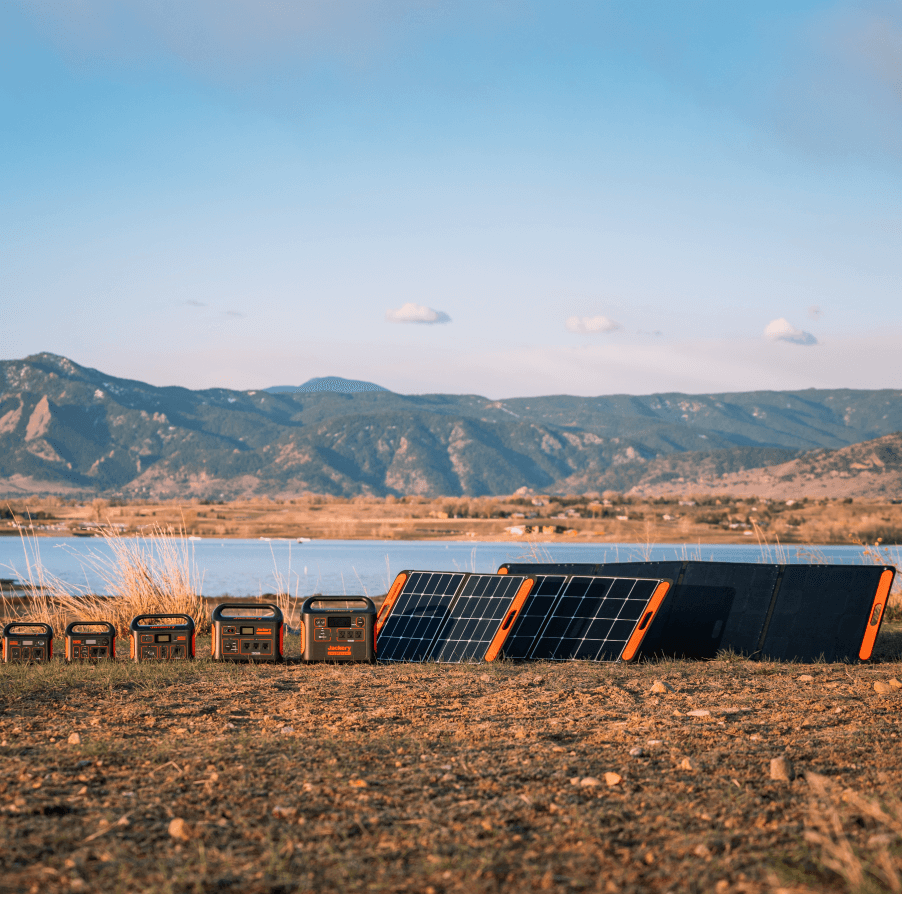

Jackery Solar Generators for Welders

Solar generators work effectively in indoor and outdoor settings. Since they help continuously supply electricity to different appliances, they are highly advisable for welding projects. You can choose Jackery Solar Generators that use the sun’s radiation to generate energy.

It’s a popular manufacturer of portable power stations and solar panels as well, known for its reliability, efficiency, and safety. The brand uses green and clean energy and is smoke and noise-free. It is also portable, making it ideal for emergencies like outages caused by rain or storms.

Jackery Solar Generator 3000 Pro

Jackery Solar Generator 3000 Pro has a large battery capacity, helping you charge your welding equipment for long hours, especially in outdoor projects or remote locations. It features double wheels and pull rods, making it portable from one place to another. It is also smoke and noise-free, making it suitable to use after sunset.

Appliances Running Hours

- 120V Welder (1200W): 1H

- Chainsaw (1200W): 1H

- Miter Saw (1800W): 4H

- Hand Drill (400W): 4H

- Angle Grinder (400W): 4H

Customer Review:

“Amazing product! Amazing price! 100% satisfied!” - Wilfredo.

Jackery Solar Generator 2000 Plus

Jackery Solar Generator 2000 Plus is also a high-power alternative to charging your welding equipment for hours. It is portable and runs on solar energy. Its large capacity ensures that you can use your tools for a longer duration with a one-time charge. It is easy to carry for on-site projects or remote locations where a power source might not be readily available.

Appliances Running Hours

- 120V Welder (1200W): 4H

- Chainsaw (1200W): 4H

- Miter Saw (1800W): 9H

- Hand Drill (400W): 3H

- Angle Grinder (400W): 4.3H

Customer Review

“Easy to set up and use, thoughtful design to have a battery mounted on wheels. Since this is a modular system, we will be adding more components in the future.” - Denise Shephard.

Jackery Explorer 2000 Plus Double Kit

The Jackery Explorer 2000 Plus Double Kit offers a large battery capacity that can be extended to ensure that your welding project runs smoothly. It combines the 2*Jackery Explorer 2000 Plus Portable Power Station in parallel, which can be safely carried to outdoor locations to charge the welding machines operating at 240V. This double kit is also helpful during emergencies when you might not have access to power for hours.

Appliances Running Hours

- 240V Welder (2400W): 4H

- Chainsaw (1200W): 8H

- Miter Saw (1800W): 9H

- Hand Drill (400W): 6H

- Angle Grinder (400W): 8.6H

Customer Review

“The 2000 Plus battery pack is an excellent way to expand your storage if you already have one of the Jackery Solar Generators in the ‘Plus’ line. No frills, easy-to-use connections, and charging times were reported. Built-in handles make carrying simple.” - Patrick Walz.

Best Practices for Welding With A Generator

It is important to follow the best practices for welding to ensure you weld safely and effectively. The practices include choosing the right generator for power source, generator capacity, proper ventilation, and grounding for a safe welding activity. Here is the list of best practices to consider before you begin your welding activity.

Choosing the Correct Type of Generator

Your welding project depends on the type of generator you use to operate your equipment. The perfect welder generator can rely on gas, diesel, inverters, or even solar energy. Ensure you keep factors such as generator portability, runtime, efficiency, and noise levels before executing your project. A Jackery Solar Generator would be ideal for charging most of your tools and devices relying on one power source.

Grounding Before Welding

Grounding is one of the key factors to consider while welding with a generator. Proper grounding prevents sudden electric shocks, circuit breakdowns, arc flashes, and welding defects.

Sufficient Ventilation

The process of welding metals and plastics releases toxic fumes into the air. While using a generator for welding indoors, use an exhaust fan or ensure the windows and doors are open for proper ventilation. When you’re welding outdoors, make sure the fumes are flowing in the opposite direction from where you’re welding.

Using the Correct Welding Technique

Choosing the correct welding technique can ensure that your generator consumes the right amount of power. Stick welding does not require much electricity and is one of the most popular welding techniques available. TIG welding operates on low-circuit arcs and uses less power than MIG welding techniques.

Using a Clean Generator

Keep your welding generator away from dirt and debris. This ensures that it runs smoothly and performs to its best output. If your generator's air filters are clogged, it can ruin its efficiency and longevity.

Avoiding Overloading

Avoid exceeding your generator's maximum power output, as this can damage it and your welding equipment. Check the manufacturer’s specifications to understand your generator's power consumption and maximum output.

Using Protective Welding Gear

Wear protective welding gear, including gloves, a helmet, and long-sleeved shirts and pants that can cover your skin. This ensures you prevent welding mishaps, arc shocks, and welding spatter.

How to Choose The Best Generator for A Welder?

Choosing the ideal generator for a welder depends on various factors, such as its size or capacity, operating quality, and type.

Size of Your Generator

It is recommended to choose the perfect size of a generator to run different welding equipment. This depends on the maximum power output of the generator drawn in Amperage (A) or Amps. You can also find a table outlining the maximum power output that can be borne by a generator size you might want to use for your welding project.

|

Max. Output |

Recommend Min Generator Size |

Recommend Ideal Generator Size |

|

Up to 130A |

6 kVA (5 kw4) |

7+ kVA (5 kw4)) |

|

140-160A |

7 kVA (5.5 kw4)) |

8+ kVA (6.5 kw4)) |

|

180–200A |

8 kVA (6.5 kw4)) |

10+ kVA (8 kw4)) |

|

250A |

13 kVA (10.5 kw4)) |

15+ kVA (12 kw4)) |

|

300A |

15 kVA (12 kw4)) |

20+ kVA (16 kw4)) |

|

350A |

25 kVA (20 kw4)) |

30 kVA (24 kw4)) |

|

400A |

35 kVA (28 kw4)) |

40 kVA (32 kw4)) |

Generator Quality

A generator typically has a THD or Total Harmonic Distortion rating. This rating refers to the amount of noise or distortion caused in a power supply. Generators with 6% or lesser THD ratings are usually safe to use and of higher quality.

Finding the Right Type of Generator

If you opt for a gas or diesel generator, you can consider spending an exorbitant amount on maintaining the gas line or purchasing diesel fuel. In comparison, inverter- and solar-powered generators are easy to use, run on clean energy, and draw less power when running a welder.

Generator for Welder FAQs

What size solar generator do I need for my welder?

To calculate this accurately, you need to consider the size of the solar generator and how much power your welder would consume.

For instance, let’s say you use the Jackery Solar Generator 2000 Plus to charge a welder drawing 1200W. You can calculate the running time of the solar generator using the following formula:

Working Hours = Battery Capacity in Wh × 0.85 ÷ Operating Wattage of the Appliances = 2042.8Wh × 0.85 ÷ 1200W = 1.44H.

Note: You should always multiply the battery capacity by 0.85 as charging appliances face adequate power loss.

Will a 7000-watt generator run a welder?

Yes, a 7000W generator can easily run a welder smoothly. A much better size for welding is a 6500 to 7000-watt generator. The minimum size of the generator for welding is 5000-5500 watts.

Can a welder damage a generator?

No. Welders cannot damage the generator since the power comes from the generator. However, an overloading or under-size generator will damage your welding equipment.

Can I use a small(er) generator to run my welder?

Yes, you can use a smaller generator to run a welder. The recommended minimum size for a generator is 6kVA.

Can you run a welder off a Generator?

Yes, a welder can be run using a generator. It depends on the size and power requirements of the welder, and ensure you equip the generator with a low voltage protection switch to protect the generator and welding equipment from power surges. To run a welder, you can opt for gas, diesel, inverter, or solar generators without a main power outlet.

Final Thoughts

A generator can help a welder maintain smooth operations during power outages and in remote areas with limited or no electricity. It can ensure a consistent supply of power for uninterrupted welding work, especially if you’re into construction or repair. Their portability and ease of use make them ideal for locations without fixed power sources.

While using a generator for welding, opt for Jackery Solar Generators to charge your welding equipment without any voltage spikes or noise emissions. Since they are portable and run on clean energy, they can help you execute your welding projects without delays.

Leave a comment